Process principle of aluminum alloy die casting shared by the China Aluminum Casting Manufacturer.

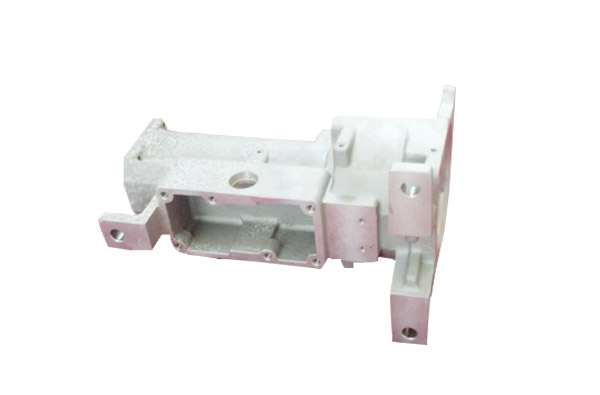

The aluminum alloy die-casting products produced by the aluminum alloy die-casting factory are only used in the electronics, automobile, electrical machinery, household appliances and some communication industries, etc., and some aluminum alloy die-casting products with high performance, high precision and high toughness produced by the aluminum alloy die-casting factory are also used in the industries with high requirements such as large aircraft and ships. The main use is in some mechanical parts.

Aluminum alloy die casting factory produces aluminum alloy die casting pieces with high dimensional accuracy, low surface roughness, high productivity, high metal utilization rate, high casting strength and surface hardness.

The principle of aluminum alloy pressing technology is to press the metal liquid into a metal mold cavity with high pressure. Cold chamber and hot chamber die casting are two basic methods of die casting technology. In cold chamber die casting, metal liquid is poured into the pressure chamber by manual or automatic pouring device, and then the metal hydraulic pressure is injected into the mold cavity by injection head. In the hot chamber die casting process, the pressure chamber is perpendicular to the crucible and the metal liquid flows into the pressure chamber automatically through the feed port on the pressure chamber. The injection punch moves downward and pushes the metal liquid through the gooseneck tube into the mold cavity. After the metal liquid solidifies, the die casting mold is opened and the casting is taken out to complete an aluminum alloy die casting cycle.

That's all for the sharing, thanks for your reading, and we also supply Custom Injection Grips products for sale, if you have any demand for our products, just feel free to contact us.

Changzhou Kadi International Trade Co.,Ltd.

Add. : Room 627, Building 24, Wuyue Square, Hutang Town, Wujin District, Changzhou,Jiangsu,China 213161

Tel : +86 519 8180 9887

Fax : +86 519 8180 9887

E-mail: info@kadi-cn.com jack@kadi-cn.com